Most of the fishing tackle rods are made of plain weave […]

Most of the fishing tackle rods are made of plain weave fiberglass cloth and unsaturated polyester composite processing, commonly known as fiberglass fishing rods. There is also a composite process made of carbon fiber and unsaturated polyester, which is called a carbon fishing rod.

Because the price of carbon fiber cloth is much higher than that of glass fiber cloth, carbon fishing rods are much more expensive than fiberglass fishing rods. The strength of carbon fiber is higher than that of glass fiber, but its own weight is very light. The made hand pole is lighter than the fiberglass hand pole under the same strength condition, so it is very popular among sports fishing enthusiasts. The rigid adjustment rod of the fishing tackle can not only use the drag force generated by moderate elasticity to buffer and protect the fishing line, but also avoid tearing the fish lips due to the excessive rigidity of the fishing rod. Moderate tonality can produce a good feel, which can add a lot of fun to fishermen. The tonality actually refers to the strength of the hand pole, which refers to how much weight can be lifted by the tip of a fully extended hand pole while the tail section remains level, and how much bending the pole body appears. The larger the weight, the smaller the bending and the harder the tune. After the fishing rod is bent under a force, the arc of the fishing rod with good uniformity is in a smooth transition state; the fishing rod with poor uniformity has a dead angle in the arc. The jointing rod is connected to the interface of the upper section.

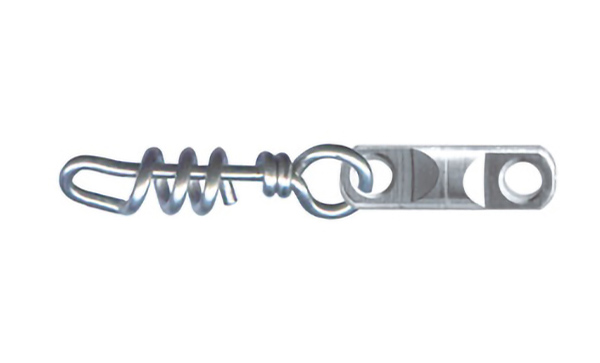

Whether the wall thickness of the socket is consistent and whether the cross section of the socket is flat is an important part of reflecting the quality of the plug rod. The way to check the socket is to slowly insert the upper section into the next section. During this process, there should be no sudden looseness or tightening. It should be inserted more tightly. After plugging tightly, there should be no shaking at the interface, and the shaking of the fishing rod has a unified feeling, and there is no noise caused by friction between the nodes due to looseness. The greater the vacuum force when pulling out each section, the tighter the upper and lower plugging. The length of the upper section of the fishing tackle rod inserted into the lower section. Each section should gradually increase the insertion amount from top to bottom. Generally, the insertion amount of the first section (pole tip) is not less than 6 cm. When using inserting poles, insert them in order from the tip of the pole, and insert them slowly and ensure that they reach the bottom. Inserting too fast will accelerate the wear of the inner and outer walls of the pole and cause looseness. After inserting a section in place, turn the inserted section counterclockwise slightly to lock the socket. The angle of rotation should not be too large, about 5 degrees is appropriate. When exiting, turn clockwise to unlock and then pull out the upper section. The braided tube (a kind of chemical fiber fabric) bonded on the tip of the pole is used to fix large threads.

After the new fishing rod is bought back, the braids need to be processed. Counting from the tip of the rod, make a knot at the length of one centimeter of the braid, cut off the excess braid, and then use a lighter to roast the braid to let it naturally melt into a small ball. This way the knot won't fall off again. Then use quick-drying super glue with good water resistance, and put a small drop of glue on the original bonding place of the braid tip, and let the glue penetrate a little above the braid tip, about 5 mm. The first is to strengthen the adhesion between the braid tip and the pole tip, and the second is to protect the braid from being worn off by the pole tip. But it must be noted that the glue must be less dripping. If the braid is fully dipped in glue and becomes stiff, the fishing line will be difficult to tighten on the braid tip, and the large line will fall off in the middle of the field. The insulating handle is made of an insulating heat-shrinkable rubber, which can be used for insulation when it is placed on the bottom of the handle. It is commonly known as the rubber cover of the anti-electric handle.

When buying an anti-electric grip, it must be about 5 cm longer than the bottom of the fishing rod, and the thickness should be as suitable as possible. If the original handle is wrapped with a layer of thread, it is best to remove the thread first and then install the anti-electric handle, so that the effect will be more beautiful, and the diameter of the handle may not be increased. Considering the heat shrinkability of the grip during installation, after putting on the insulating grip, the grip should be flush with the end of the bottom of the fishing rod. Then use an electric hair dryer of more than 1000 watts to gradually heat it until the sleeve is shrunk and wrap the bottom handle tightly, and then use a cutter to cut off the excess part. It can be heated directly on an open flame, but the action must be fast to avoid burning the bottom handle.